Bringing the innovative idea for a new and original product to life is one of the biggest hurdles to modern-day entrepreneurs. Make no mistake, though, developing a new product from scratch can be a daunting process for even the most prominent minds of current product manufacturing industry leaders.

And developing a new product from scratch is not something that happens overnight but a multi-step journey where everything begins with an innovative idea and should result in mass-production of the end-product of that very same idea.

Suppose you ask ten prolific business owners to tell you the story behind their success. In that case, you’ll hear ten different stories, just to find out that the journey to a high-selling end-product rarely resembles a straight line and is always somewhat different. But, there’s one step of the process that’s always there: that idea’s fully-functional prototype.

Having the right sketches, blueprints, renders, and videos of a particular new product design are excellent. Still, suppose you’re looking to mass-product your next significant invention and get the backing of investors to help you get your innovative idea to product shelves around the world. In that case, you will most certainly need a prototype along the way.

What is a fully-functional prototype?

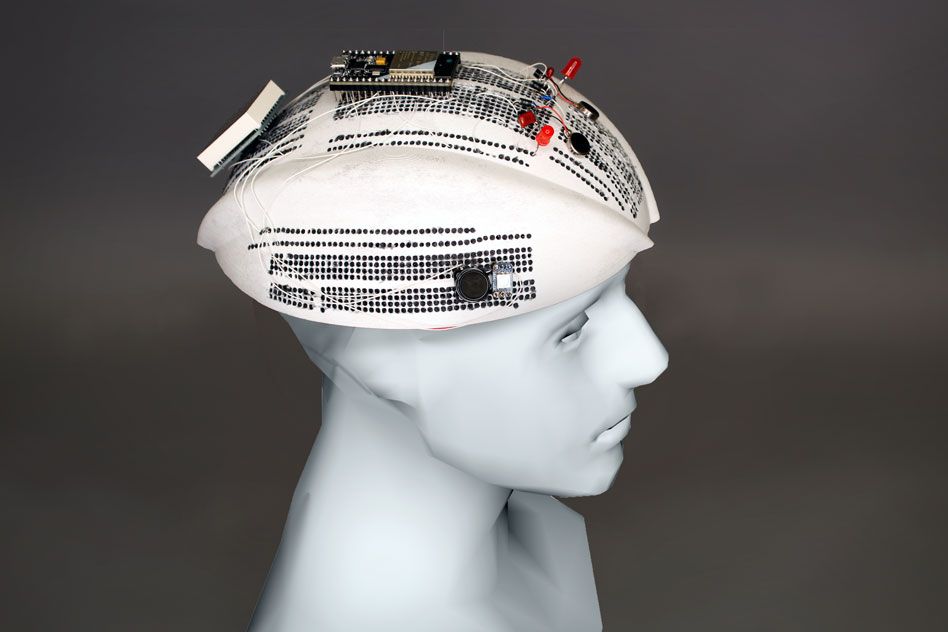

A fully-functional prototype is an early sample, a model, an initial release of a product that can be replicated or learned from. The prototype is essential so that you can test your work, make some design improvements, determine what’s wrong and needs to be changed, figure out if there’s a need to enhance some of its features, and make it more precise before it goes into mass-production.

Originating from the ancient Greek word prototypon (πρωττυπον) that means “primitive form” and is a derivate of primitive, original, first, and impression, a prototype definitely serves as being the first impression of something. A fully-functional prototype will permit the evaluation of a new product in a convenient form as it translates a good blueprint into a representative three-dimensional item.

Initial considerations

A lot of entrepreneurs make the most use of their prototypes during the process of funds generation. Prospective clients and investors may visualize the end product much better with the help of a fully-functional prototype.

Nevertheless, the stage of prototype development demands paying a lot of attention to controlling potential cost overruns. That’s why crafting a realistic budget and adhering to financial constraints is a must, and it’s for the best to work with experienced prototype developers.

Depending on the industry’s nature, the capacity for future production, the market’s potential, and the available budget can all make a significant difference in how you develop the functional model of your prototype.

Prototype developer teams enjoy at least three options for creating prototypes of potential products, including DIY construction, employing a 3D printer, or retaining rapid prototyping services from experienced and trustworthy industry professionals.

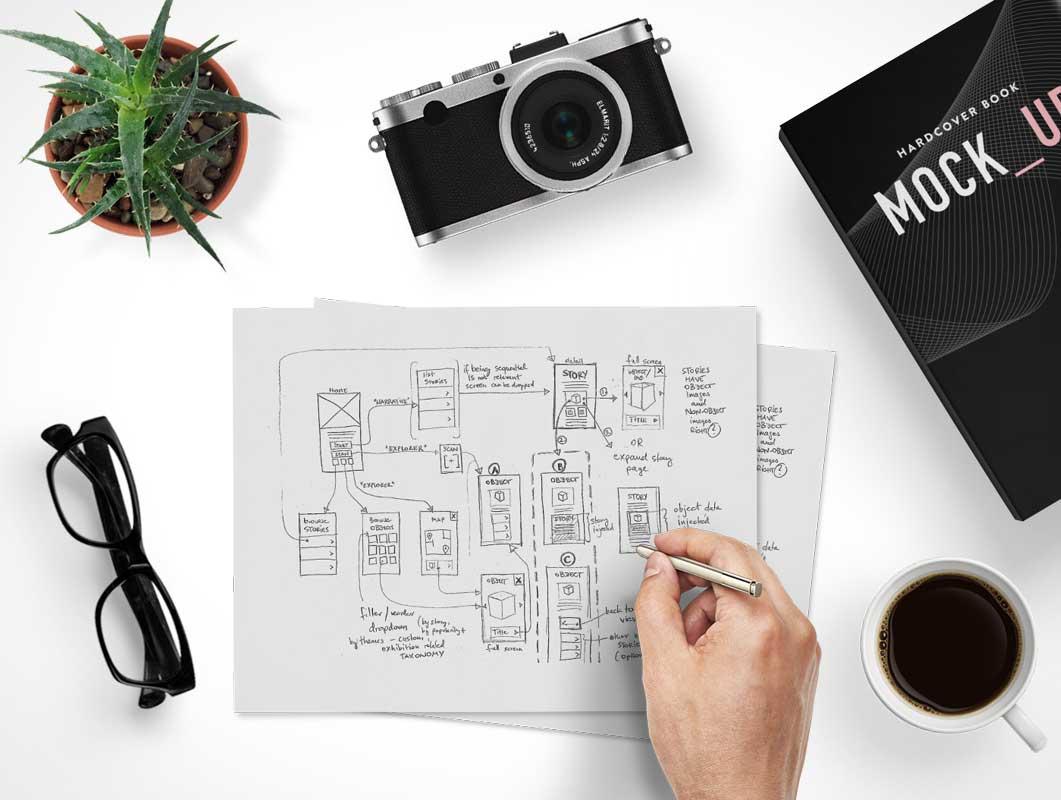

Step 1: Sketches and blueprints

Most of the prototype development teams begin creating a fully-functioning prototype by coming up with sketches of an end product or a proposed innovation. The other iterative series of progressively changing the drawings may lead to a CAD-generated design or a complete blueprint.

The first step of the process is a significant accomplishment in the development process. Also, don’t forget to obtain adequate legal protection for your intellectual property at the beginning of the design process. Consult with your legal team and patent, trademark, and copyright your work to secure the potential benefits in the future.

Step 2: Manufacture a prototype

Manufacturing a prototype can begin with DIY construction efforts on the part of the inventor or entrepreneur. Many talented people possess the ability to create fully-functional initial models of products. Besides, the recent popularity of 3D printers has enabled the creation of inexpensive plastic and metal models of particular items and cost-efficient prototypes.

Still, the best option for developing a prototype usually involves employing a professional service with sufficient capabilities and expertise to furnish ongoing design and construction support services during the most critical phase of the product development process. These specialized services can offer realistic material options and recommend alternative and cost-effective methods for accomplishing the desired design during the prototype building phase.

Step 3: Ongoing prototype iterations

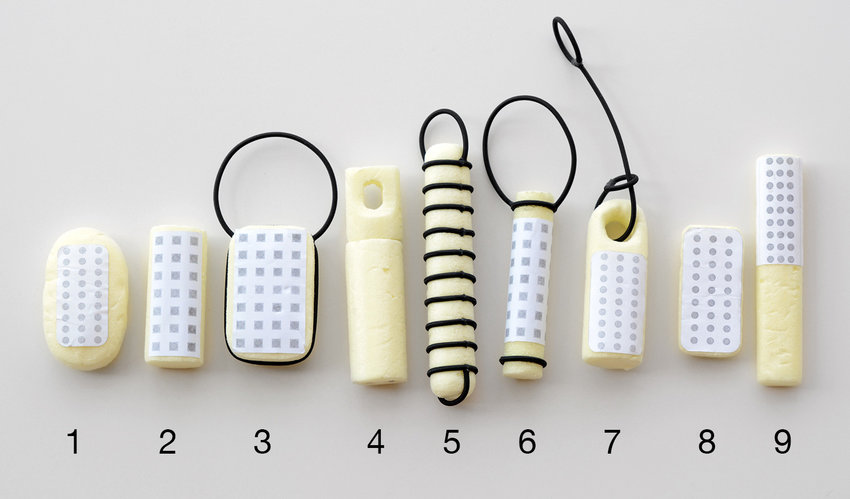

In most cases, the initial prototype doesn’t become the final model for a new product overnight. The development team may rely upon this phase to assist, modify, and reformulate specific features on the proposed product’s initial prototype.

Working with a prominent and competent prototype manufacturing company can prove exceedingly helpful during this step. On many occasions, the design team should evaluate numerous possible solutions to the initial prototype problems. Also, comparing working prototypes side-by-side may considerably assist in this process. It can offer invaluable assistance in assessing and potential marketing and promotional aspects of the final product.

Once you make the necessary changes to the initial prototype, now you’re ready to produce your fully-functional prototype that will undoubtedly expedite the whole process of bringing your innovative idea of a new product design to market.

Step 4: Manufacturing a limited edition of the fully-functioning prototype

The last step in prototype development typically involves undertaking a limited production run. Producing this limited edition of fully-functional prototypes permits the development team to test the product on target markets against competitors’ products or focus groups.

As samples can permit potential investors and clients to appreciate the invention’s commercial potential fully, this run will also enable the marketing team to showcase a particular product more effectively.

Besides, producing limited quantities of a new product design will allow the development team to submit the necessary samples for testing labs and reviewers.

Final words

Developing fully-functional prototypes helps entrepreneurs and inventors bridge the gap between a fantastic innovative idea and a marketable product. By creating a functional and tangible model, you’ll be able to present your creation more effectively to clients and potential investors.

Generally, obtaining prototype production services from a highly-experienced and professional prototype manufacturing company offers the best way to implement your next big project.

Share Your Thoughts